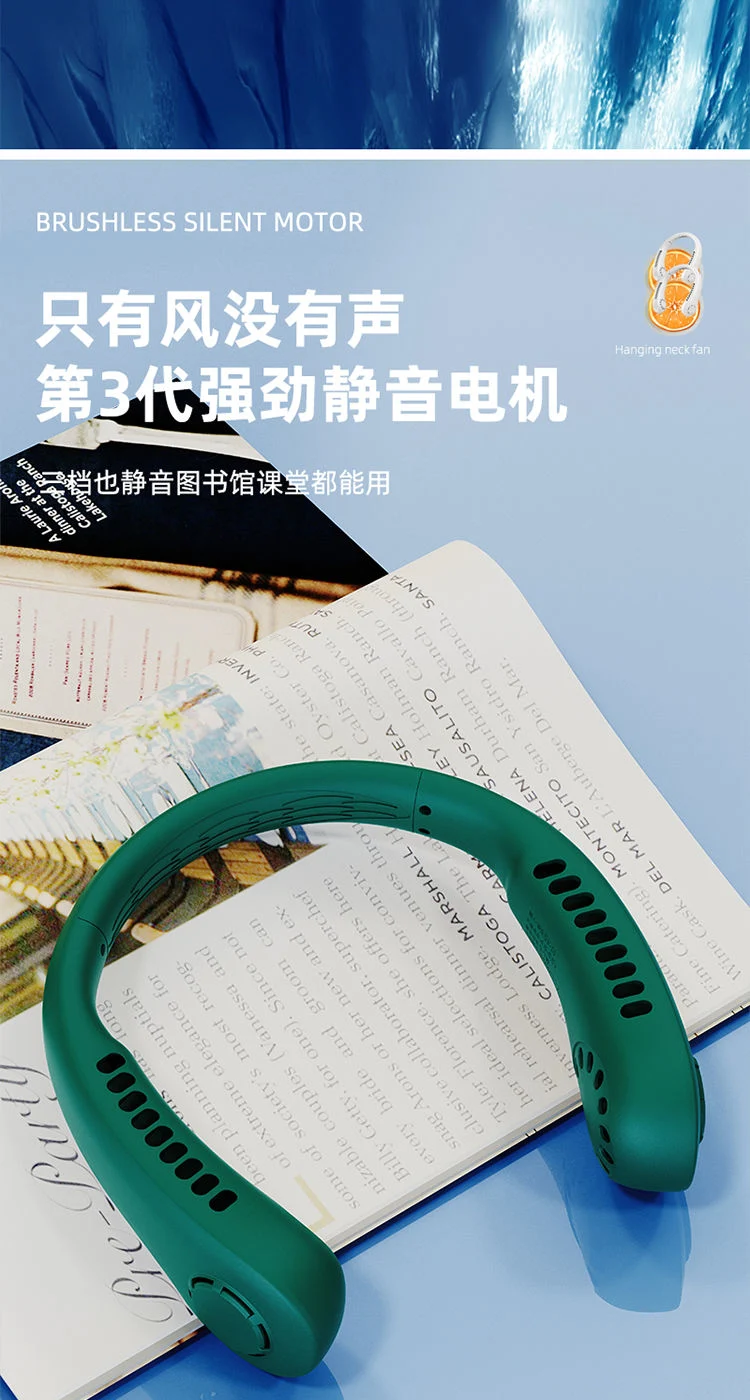

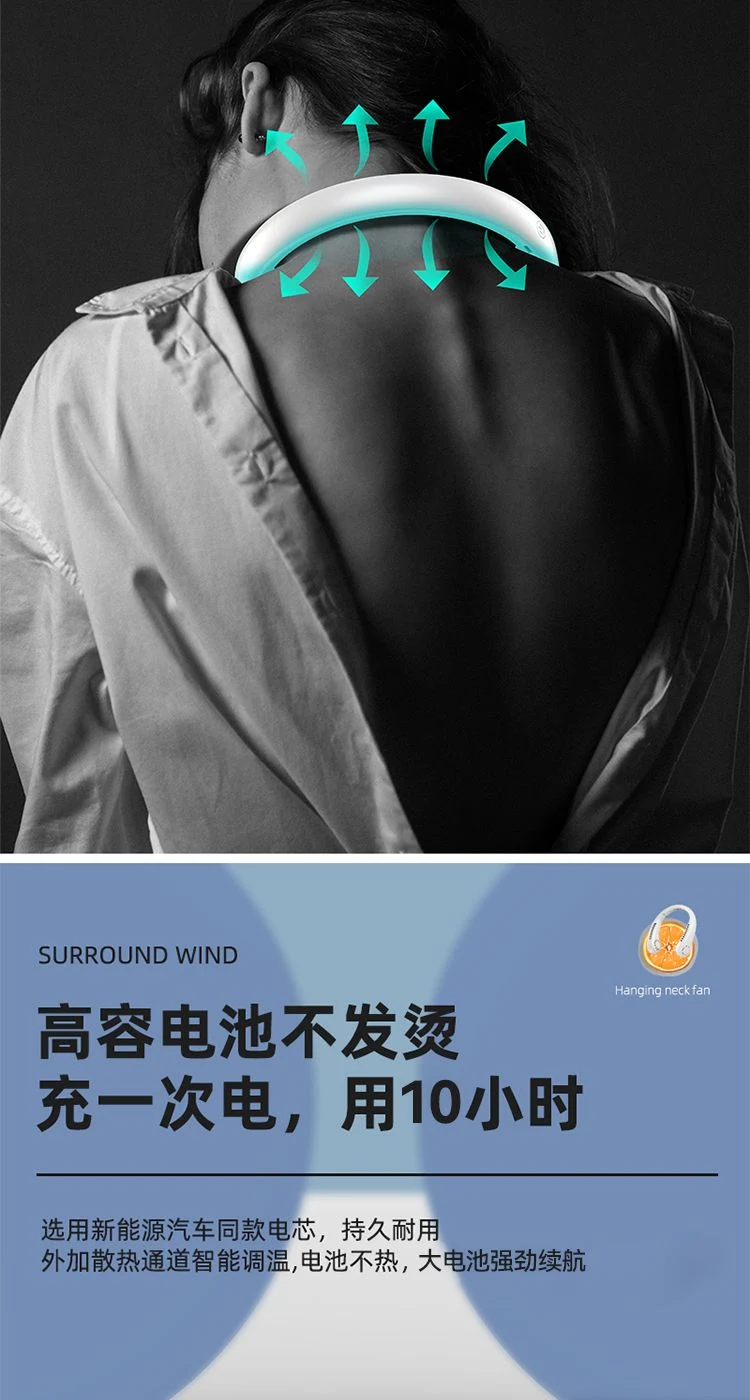

2023 New Lazy Folding Leafless Hanging Neck Fan Hanging Neck USB Charging Outdoor Portable Head-Mounted Hanging Neck Fan

Package size per unit product 197.00cm * 160.00cm * 40.00cm Gross weight per unit product 0.400kg Our company supplies d

Basic Info

| Model NO. | KD55 |

| Mould Cavity | Single Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | HASCO |

| Customized | Customized |

| Design | Per Drawing or Sample |

| Guarantee | 1 Year |

| Lead Time | 30 Days |

| Delivery Date | 15-20 Days |

| Transport Package | PP Bag, Carton |

| Specification | RoHS, ISO 9001, ISO 14001 |

| Trademark | KANG DE |

| Origin | Dongguan, China |

| HS Code | 3903900000 |

| Production Capacity | 1, 000, 000 PCS / Month |

Packaging & Delivery

Package size per unit product 197.00cm * 160.00cm * 40.00cm Gross weight per unit product 0.400kgProduct Description

Our company supplies different kinds of injection moulds, injection plastic products, plastic parts, plastic electronic parts, phone case, car parts, etc. High quality and favorable price. For more information, please contact us directly. We're pleased to get your Inquiry and we will come back to as soon as possible.Plastic Injection Product with ISO SGS

1. Material: Polyamide, Silicone, EPDM, NBR, SBR, PVC, Polyurethane, ABS and so on.

2. Mold life time: 500000~+1, 000, 000 shots

3. Color: Black, Red, Clear, White, etc per PANTONE

4. Lead time: Mould 3-5 weeks, order per Qty

5. OEM & ODM are welcome.

6. Packaging: Standard exprot packing ( PVC bag, Carton, Pallet) or per customer design

7. Port: Shenzhen Port

8. Certification: ISO 9001, ISO 14001, RoHS

9. We also accept the small quantity as the trying order.

Dongguan Kang De Electronics Factory

Address: Street Officer Tseng Tau 3, Fumin Road, Feng Gang Town, Dongguan, Guangdong, China

Post code: 523705

1. Quote | According to sample, drawing and specific requirement |

| 2.Discussion | Material, price, lead time, payment term, etc. |

| 3.Contract Signature | Approval for all the items |

| 4.Deposit | 50% deposit by T/T |

| 5.Sample Testing | Send sample to customer for confirmation |

| 6.Mass Plastic Injection Componentoduction | Start to produce |

| 7.Inspect before package | We inspect each pcs before package to insure the quality |

| 8.Package | We pack parts as we have discussed and send the photos and needed documents before shipment |

| 9.Balance | Customer pay the balance 50% before shipment |

| 10.Shipment | Delivery the goods |

Send to us